Wheel Stud Troubles: Lug Nuts Spinning – A Comprehensive Guide

Imagine this: you're changing a tire, and suddenly, the lug nut spins freely, but doesn't tighten. The wrench turns, the nut spins, but nothing engages. This frustrating scenario points to a likely culprit: a spinning wheel stud. This seemingly minor issue can lead to major safety concerns if left unaddressed. This comprehensive guide delves into the intricacies of spinning wheel studs and loose lug nuts, providing you with the knowledge and solutions you need to keep your wheels firmly on the ground.

A spinning wheel stud occurs when the stud, responsible for securing the wheel to the hub, becomes stripped or damaged, preventing the lug nut from properly engaging. This can happen due to various reasons, including cross-threading, over-torquing, corrosion, and wear. Understanding the underlying cause is crucial for effective repair.

While the exact origin of wheel studs is intertwined with the development of the automobile, their importance has remained constant. These small but vital components are the linchpin of wheel safety, ensuring that your wheels remain securely fastened to your vehicle. The issue of spinning wheel studs has been a persistent challenge since their inception, often linked to improper installation or maintenance practices.

The primary issue with a spinning wheel stud is compromised wheel security. A loose wheel can lead to wobbling, vibration, and even detachment, creating a serious safety hazard for you and other drivers. Ignoring a spinning stud can also damage the wheel hub, leading to more extensive and costly repairs. Addressing the problem promptly is essential.

Essentially, the wheel stud is a threaded bolt embedded in the wheel hub. The lug nut, a fastener with internal threads, screws onto the wheel stud, clamping the wheel securely against the hub. When the stud's threads are damaged or stripped, the lug nut can't grip, leading to the "spinning" sensation. For example, imagine trying to screw a nut onto a bolt with stripped threads. The nut will spin freely without tightening.

One benefit of addressing a spinning wheel stud quickly is enhanced safety. A properly secured wheel ensures stability and control, minimizing the risk of accidents. Another advantage is preventing further damage. A spinning stud can damage the hub, leading to more extensive repairs. Finally, addressing the issue promptly saves money in the long run by avoiding costly repairs down the line.

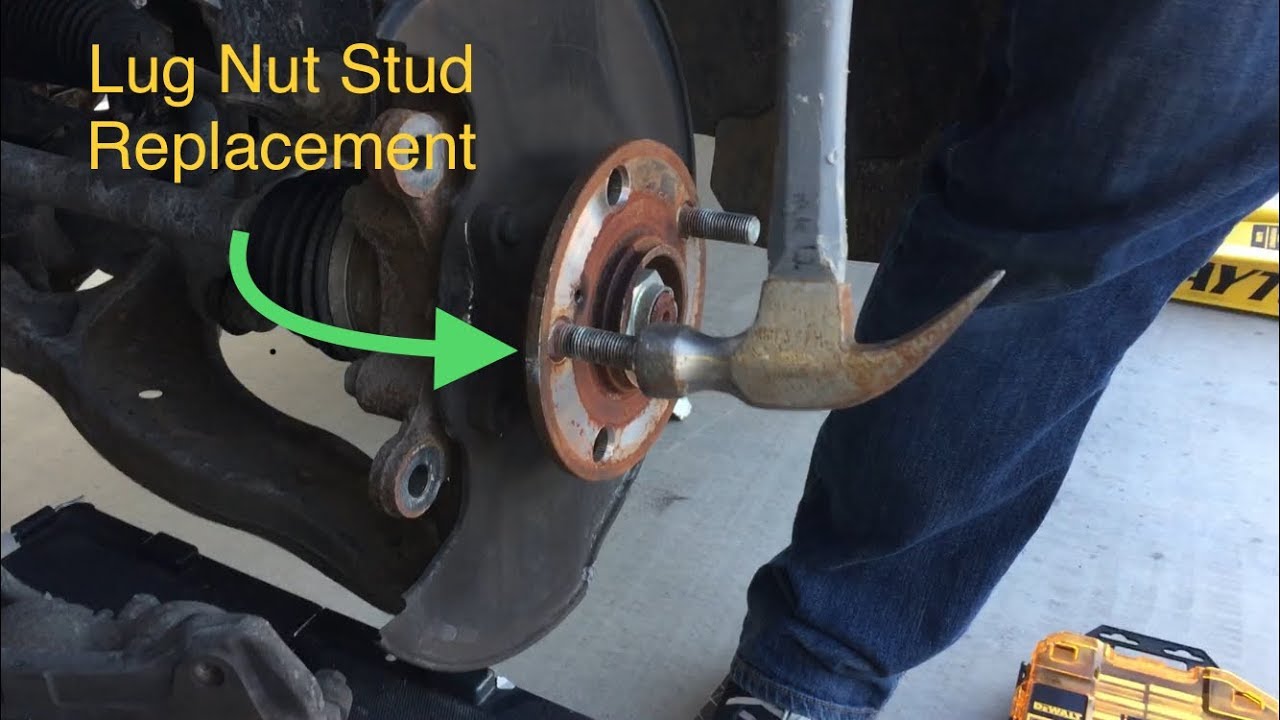

If you encounter a spinning wheel stud, inspect the extent of the damage. If the stud is significantly stripped, it will need replacing. If the damage is minor, sometimes a new lug nut can provide a temporary fix. However, replacing the damaged stud is always the recommended course of action for long-term safety and reliability. Consult a qualified mechanic for a proper diagnosis and repair.

Advantages and Disadvantages of Dealing with a Spinning Wheel Stud

| Advantages | Disadvantages |

|---|---|

| Increased safety | Can be time-consuming to repair |

| Prevents further damage | May require professional assistance |

| Saves money long-term | Can be inconvenient |

Best practices include using a torque wrench to tighten lug nuts to the manufacturer's specifications, avoiding cross-threading, regularly inspecting wheel studs for damage or corrosion, and addressing any issues promptly.

Frequently Asked Questions about Wheel Stud and Lug Nut Issues:

Q: What causes a wheel stud to spin? A: Several factors, including over-torquing, cross-threading, corrosion, and wear.

Q: Can I drive with a spinning wheel stud? A: No, it’s unsafe. Have it repaired immediately.

Q: How do I fix a spinning wheel stud? A: A qualified mechanic should replace the damaged stud.

Q: How can I prevent wheel stud issues? A: Use a torque wrench, avoid cross-threading, and inspect studs regularly.

Q: What are the signs of a bad wheel stud? A: Spinning lug nuts, wobbling wheels, and unusual noises.

Q: How much does it cost to replace a wheel stud? A: The cost varies but is typically a relatively inexpensive repair.

Q: Can I replace a wheel stud myself? A: While possible, it's recommended to have a professional handle the repair.

Q: What tools do I need to replace a wheel stud? A: Specialized tools are often required, making professional repair advisable.

A simple tip for preventing wheel stud issues is to ensure your lug nuts are properly tightened using a torque wrench to the manufacturer's recommended specifications. This can prevent over-torquing, a common cause of stud damage.

In conclusion, a spinning wheel stud is a serious safety concern that should never be ignored. By understanding the causes, solutions, and preventative measures outlined in this guide, you can ensure the safety and reliability of your vehicle. Remember, properly functioning wheel studs are critical for keeping your wheels securely attached and preventing potentially dangerous situations. Regular inspections, proper tightening techniques, and prompt repairs are crucial for maintaining wheel integrity and ensuring a safe driving experience. Don't underestimate the importance of these small but vital components – your safety depends on them. Take action today to inspect your wheel studs and address any potential issues to enjoy peace of mind on the road.

Dive headfirst into the world of reverse harem romance anime

Tiktok symbol magic copying and pasting your way to viral fame

Embrace your inner fire exploring feminine phoenix tattoo designs