Unlocking the Mysteries of SAE Wrench Set Sizes

Ever stared at a bolt, wrench in hand, feeling a flicker of doubt? Is it a 1/2 inch? 5/16? Choosing the correct SAE (Society of Automotive Engineers) wrench size can feel like a cryptic puzzle, but understanding these fractional measurements is crucial for any DIY enthusiast or professional mechanic. This guide will demystify SAE wrench set sizes, providing you with the knowledge to confidently tackle any project.

SAE wrenches are ubiquitous in American workshops and garages. Their fractional inch measurements distinguish them from their metric counterparts. But why fractions? Why not decimals? The answer lies in the history of American manufacturing, where fractions were the standard long before the metric system gained traction. This legacy continues, making familiarity with SAE wrench sizes essential for working on everything from classic cars to household appliances.

The SAE system, established in the early 20th century, standardized various aspects of engineering, including fastener sizes. This standardization brought order to a previously chaotic landscape of proprietary sizes, facilitating interchangeability and simplifying manufacturing. SAE wrench sets became essential tools, ensuring that mechanics and individuals could easily find the right fit for a given bolt or nut.

One of the main issues with SAE wrench sizes is the sheer number of them. A comprehensive set can contain dozens of individual wrenches, differing by minute increments. This can be overwhelming for beginners and even experienced users occasionally struggle to differentiate between closely related sizes. A good quality wrench set with clear markings is essential to avoid frustration and potential damage to fasteners.

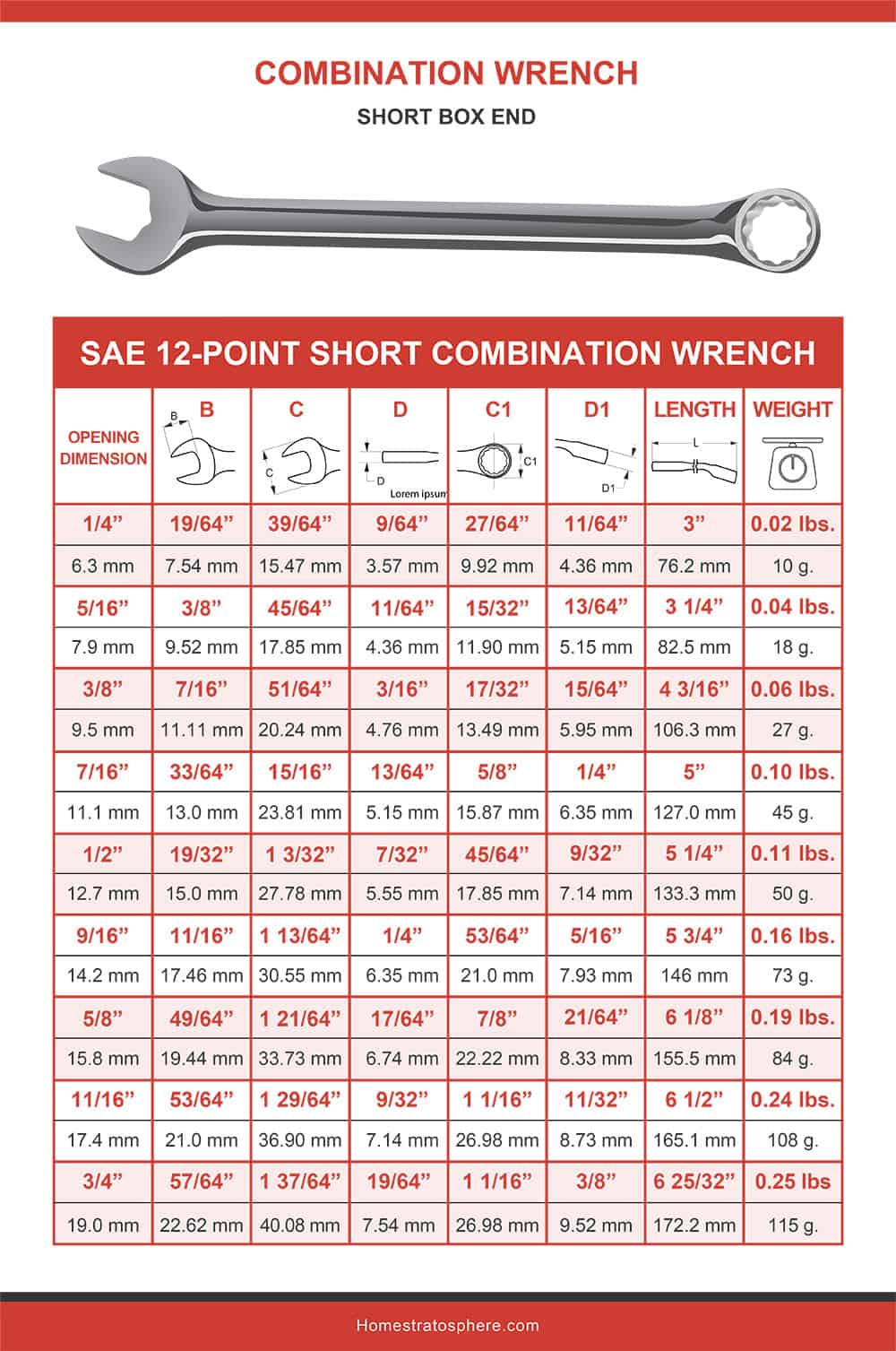

SAE wrench sizes are expressed as fractions of an inch. Common sizes include 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, 13/16, 7/8, 15/16, and 1 inch. These sizes correspond to the diameter of the fastener they are designed to grip. For instance, a 1/2 inch wrench fits a 1/2 inch bolt or nut.

One benefit of using the correct SAE wrench size is preventing damage to fasteners. Using a wrench that is too large or too small can strip the head of a bolt or nut, rendering it unusable. Another benefit is increased efficiency. Having the correct wrench at hand saves time and frustration, allowing for smoother workflow. Finally, using the correct SAE wrench size promotes safety. A properly fitted wrench provides a secure grip, reducing the risk of slippage and potential injury.

Building a complete set of SAE wrenches is an investment. Start with a basic set covering the most common sizes. As your needs evolve, expand your collection with less frequent sizes. High-quality wrenches, although more expensive initially, offer greater durability and precision.

Advantages and Disadvantages of SAE Wrench Sets

| Advantages | Disadvantages |

|---|---|

| Widely available in North America | Not universally compatible with metric fasteners |

| Long-standing standard for many applications | Large number of sizes can be confusing |

| Extensive range of sizes for diverse needs | Requires familiarity with fractional inch measurements |

Best Practices:

1. Organize your wrenches: Keep your SAE wrenches organized in a toolbox or on a wall-mounted rack for easy access.

2. Use the correct wrench for the job: Avoid using adjustable wrenches or pliers as substitutes for properly sized SAE wrenches.

3. Clean and lubricate your wrenches: Regularly clean and lubricate your wrenches to prevent rust and corrosion.

4. Inspect your wrenches for wear and tear: Replace any damaged or worn-out wrenches to ensure safe and effective use.

5. Store your wrenches in a dry place: Protect your wrenches from moisture and humidity to prevent rust.

FAQ:

1. What does SAE stand for? Society of Automotive Engineers.

2. What is the difference between SAE and metric wrenches? SAE uses fractional inch measurements, while metric uses millimeters.

3. What is the most common SAE wrench size? 1/2 inch is frequently used.

4. Can I use an adjustable wrench instead of a SAE wrench set? While possible in a pinch, adjustable wrenches don't offer the same precision or grip.

5. How do I determine the correct SAE wrench size? Measure the fastener head with a caliper or ruler.

6. What are the benefits of a ratcheting SAE wrench? Ratcheting wrenches allow for faster turning without needing to remove and reposition the wrench.

7. Where can I buy a SAE wrench set? Hardware stores, automotive parts stores, and online retailers.

8. How do I care for my SAE wrenches? Keep them clean, lubricated, and stored in a dry location.

Tips and Tricks:

Use a wrench organizer to keep your set neatly arranged. A magnetic tray can prevent wrenches from rolling around in your toolbox.

Understanding and utilizing the correct SAE wrench set sizes is a fundamental skill for anyone working with mechanical fasteners. From the historical context of their fractional inch measurements to the practical benefits of preventing damage and ensuring efficiency, SAE wrenches play a vital role in countless applications. By investing in a quality set, organizing your wrenches, and following best practices, you can confidently tackle any project requiring these essential tools. Mastering SAE wrench sizes empowers you to work efficiently, safely, and effectively, ultimately unlocking a world of possibilities in DIY projects and professional endeavors alike. Remember to choose the correct wrench for the job, maintain your tools, and continue to expand your knowledge of SAE wrench sizes as your skills and projects evolve. The right tools, coupled with the right knowledge, pave the way for successful and satisfying work. This comprehensive understanding will transform you from a hesitant novice to a confident master of your tools, allowing you to tackle any mechanical challenge with precision and ease. Embrace the world of SAE wrenches and unlock the potential within your toolbox and yourself.

Aston martin titanium grey the ultimate guide

Benjamin moore exterior black paint everything you need to know

Newarks canvas exploring sherwin williams in delaware