The Quiet Art of Mechanical Clock Repair

There's a certain quiet elegance to a mechanical clock, a rhythmic pulse that whispers of time's passage. It's not just a timekeeping device; it's a piece of history, a miniature marvel of engineering. But what happens when this intricate dance falters? What if the steady tick-tock becomes a stutter, or worse, silence? This is where the art of mechanical clock repair comes into play, a craft that blends patience, precision, and a deep appreciation for the mechanics of time.

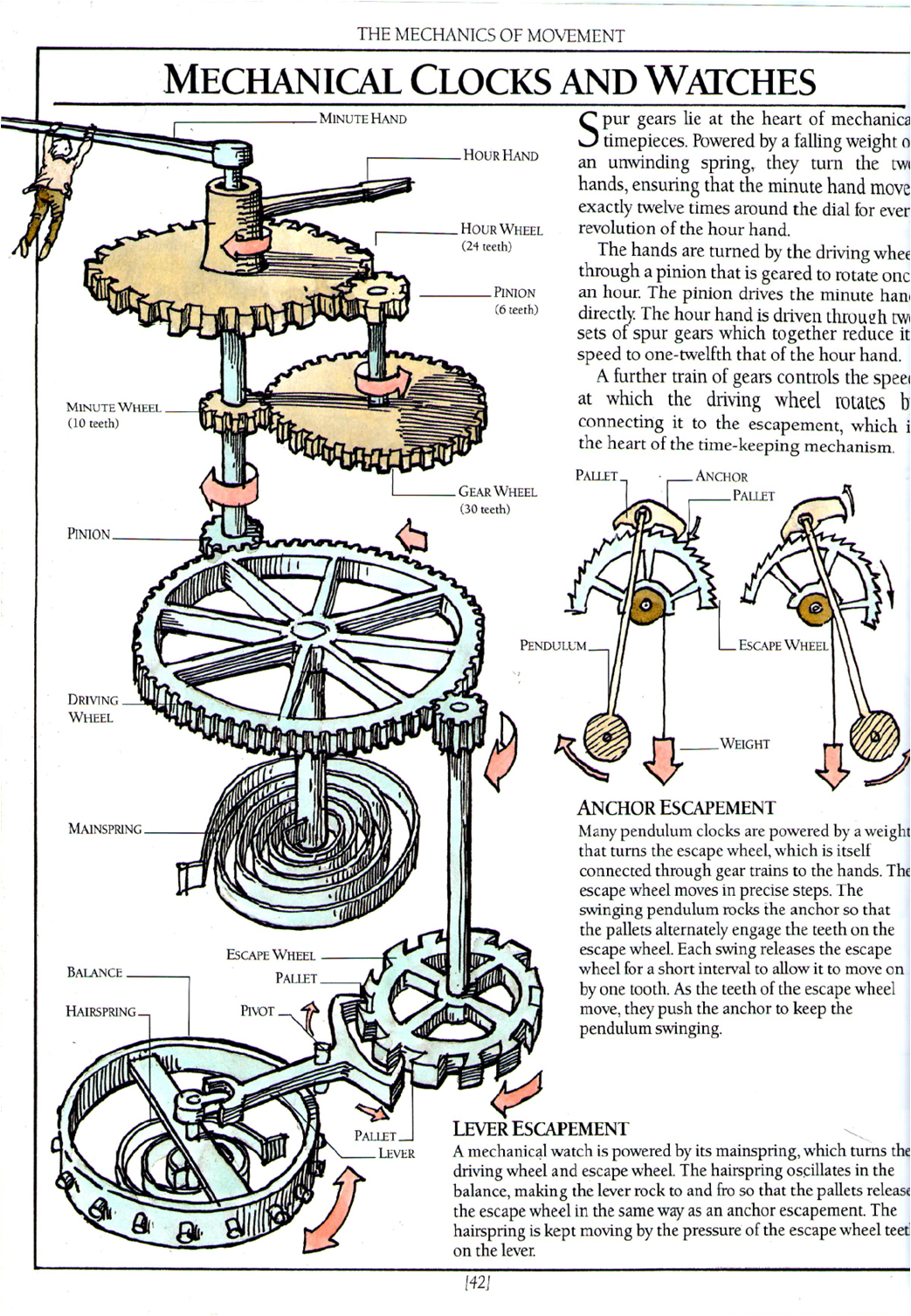

Understanding the mechanics of a clock is akin to understanding a complex, miniature city. Gears mesh, springs unwind, levers pivot, all working in harmony to translate stored energy into the measured movement of hands across a dial. Knowing how to diagnose issues and perform repairs is a skill that allows you to preserve these intricate machines, keeping their stories alive for generations to come. From the simplest cleaning and lubrication to the more complex tasks of replacing worn parts, mechanical clock repair is a journey into the heart of these fascinating mechanisms.

The history of mechanical clock repair is intertwined with the history of clockmaking itself. From the earliest verge escapements to the more precise anchor escapements, the evolution of clock technology has necessitated the development of corresponding repair techniques. As clocks became more complex, so too did the skills required to maintain them. This historical perspective underscores the importance of understanding the specific type and era of the clock you're working with, as different mechanisms require different approaches.

Common issues in mechanical clocks often stem from wear and tear, lack of lubrication, or environmental factors like dust and humidity. A clock that runs slow or fast may indicate a problem with the escapement or the pendulum. A clock that stops altogether could be due to a broken mainspring or a jammed gear train. Identifying the root cause of these problems is the first step towards successful repair.

Learning to repair a mechanical clock is like learning a new language. You need to familiarize yourself with the vocabulary of gears, pinions, escapements, and pendulums. Understanding how these components interact is crucial for accurate diagnosis and effective repair. For example, the escapement, the heart of the clock, regulates the release of energy from the mainspring, translating it into the oscillatory motion of the pendulum or balance wheel. Understanding this interplay is fundamental to troubleshooting and repair.

One of the primary benefits of learning to repair a mechanical clock is the preservation of these historical artifacts. By keeping these intricate machines running, we’re maintaining a tangible connection to the past. Another benefit is the satisfaction of bringing something back to life, the quiet pride in restoring a piece of history to its former glory. Finally, it's a skill that can be incredibly rewarding, offering a tangible connection to the intricate world of mechanical engineering.

A simple action plan for repairing a mechanical clock might involve: 1. Assessment: Carefully examine the clock for visible damage or signs of wear. 2. Diagnosis: Identify the specific issue causing the malfunction. 3. Disassembly: Carefully take apart the clock, documenting each step. 4. Repair/Replacement: Clean, lubricate, repair, or replace damaged parts. 5. Reassembly: Put the clock back together, following the documentation. 6. Testing: Verify that the clock is functioning correctly. 7. Adjustment: Fine-tune the clock's accuracy.

Advantages and Disadvantages of Repairing a Mechanical Clock

| Advantages | Disadvantages |

|---|---|

| Preservation of historical artifacts | Can be time-consuming |

| Personal satisfaction | Requires specialized tools and knowledge |

| Development of valuable skills | Can be costly for certain repairs |

Frequently Asked Questions:

1. What tools do I need to repair a mechanical clock? - Basic tools include screwdrivers, tweezers, a loupe, and oilers.

2. Where can I find parts for my clock? - Clock supply stores, online retailers, and antique shops.

3. How often should I service my clock? - Generally every 3-5 years, depending on the clock and environment.

4. What type of oil should I use? - Specialized clock oil, not household oils.

5. How do I adjust the timekeeping accuracy? - This usually involves adjusting the pendulum length or regulating the escapement.

6. What are common signs of a problem? - Stopping, running slow or fast, unusual noises.

7. Can I repair my clock myself? - Simple repairs are possible, but complex issues may require professional help.

8. Where can I learn more about clock repair? - Books, online resources, and local clock repair workshops.

In conclusion, the art of mechanical clock repair is more than just a practical skill; it's a connection to history, a celebration of intricate engineering, and a testament to the enduring appeal of these timeless machines. By understanding the mechanics of these intricate devices, diagnosing common issues, and mastering the techniques of repair, we can ensure that these pieces of history continue to tick for generations to come. The journey into the heart of a mechanical clock is a journey into the heart of time itself, a rewarding experience that connects us to the past while preserving it for the future. Take the time to learn, to explore, and to keep the quiet elegance of these mechanical marvels alive.

Taming the wild coway outdoor water filtration

Getting your dream ridgeline your way honda ridgeline ordering guide

Unlocking the rustic charm exploring barnwood hardwood flooring