Keep Your Suzuki Outboard Purring Impeller Maintenance

Is your Suzuki outboard struggling to keep its cool? Overheating can be a serious issue, leading to costly repairs and potentially ruining a day on the water. One of the most common culprits behind outboard overheating is a worn-out impeller. This small but vital component is responsible for circulating cooling water through the engine. Understanding its function and how to replace it is crucial for any Suzuki outboard owner.

The impeller, a rubber vane pump within the lower unit of your outboard, draws water in and pushes it through the cooling system to regulate engine temperature. Over time, the impeller's rubber vanes can wear down, crack, or become brittle due to heat, age, or debris in the water. A damaged impeller restricts water flow, resulting in reduced cooling efficiency and potential overheating. Regularly servicing and replacing your impeller is a proactive step towards avoiding these problems.

The importance of a functioning impeller cannot be overstated. Imagine your car's radiator failing – the engine would quickly overheat and seize. The impeller performs a similar function for your outboard. By maintaining a consistent flow of cooling water, it prevents overheating, ensures optimal engine performance, and extends the life of your outboard.

Issues related to a failing impeller often manifest as a rise in engine temperature, a decrease in water pressure from the tell-tale stream, or even steam coming from the engine cowling. Ignoring these warning signs can lead to significant damage and expensive repairs. Regular impeller maintenance is a relatively inexpensive preventative measure compared to the potential cost of a blown head gasket or other major engine problems.

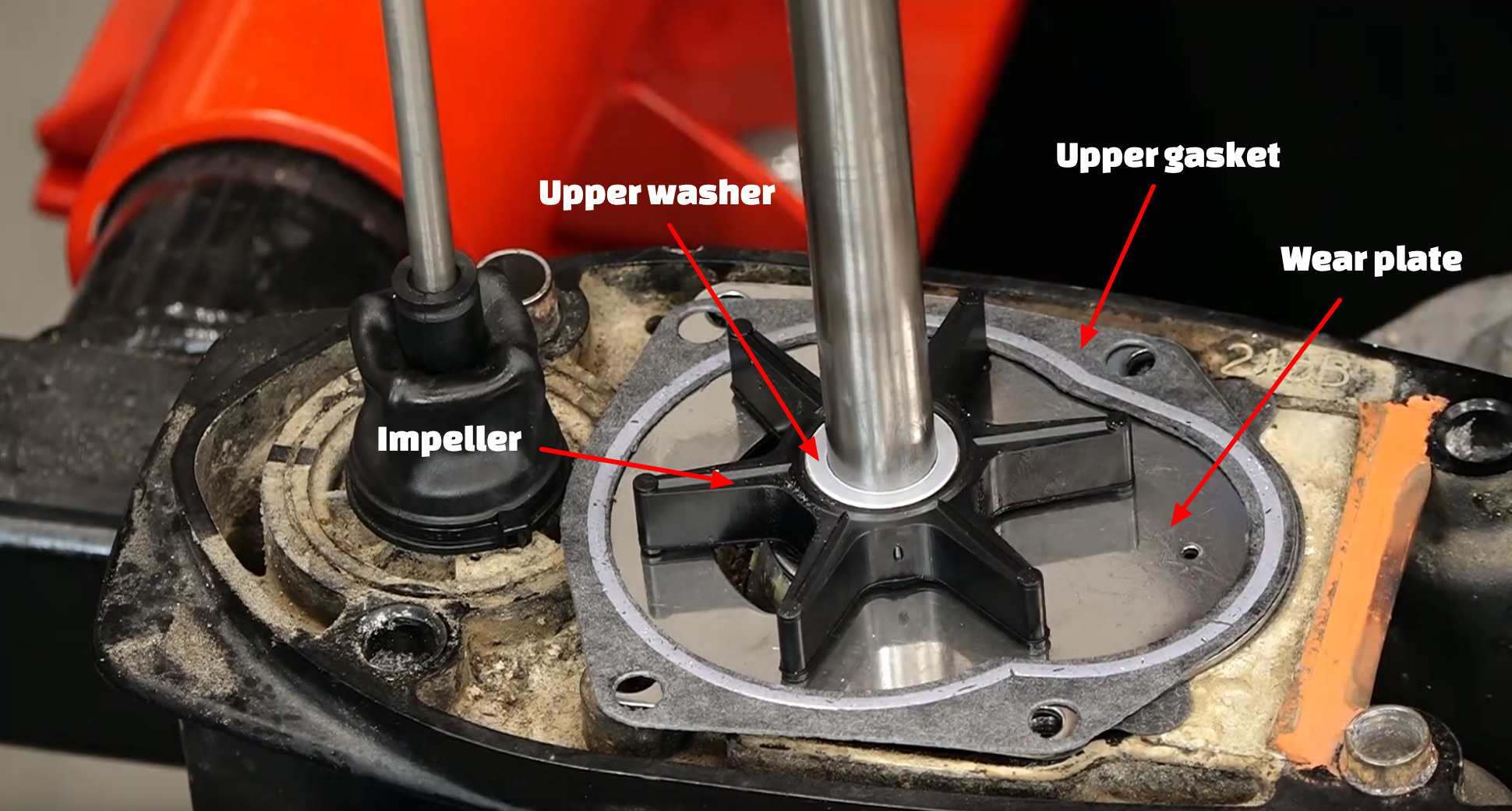

Understanding the process of replacing an impeller is empowering and can save you a trip to the mechanic. While the specific steps may vary slightly depending on the model of your Suzuki outboard, the general principles remain consistent. Typically, the process involves removing the lower unit, accessing the impeller housing, removing the old impeller, installing the new impeller, and reassembling the lower unit. It's a task well within the capabilities of most boat owners with basic mechanical skills.

Three significant benefits arise from regular impeller replacement: preventing overheating, ensuring optimal engine performance, and extending the outboard's lifespan. A fresh impeller ensures sufficient cooling water flow, preventing overheating-related damage. Consistent cooling leads to better engine performance, smoother running, and improved fuel efficiency. Finally, by avoiding overheating and related stresses, you're proactively extending the operational life of your outboard motor.

Creating an action plan for impeller replacement involves regularly inspecting the impeller for wear and tear, keeping a spare impeller onboard, and scheduling replacement every one to two years, or as recommended by Suzuki for your specific model. Successfully implementing this plan involves keeping track of operating hours and making impeller replacement a routine part of your outboard maintenance schedule.

A checklist for changing a Suzuki outboard impeller would include gathering the necessary tools, purchasing the correct impeller for your model, having a new impeller housing gasket ready, and ensuring you have a container to drain lower unit oil.

A step-by-step guide for impeller replacement involves disconnecting the shift linkage, removing the lower unit bolts, carefully separating the lower unit from the outboard, locating and opening the impeller housing, removing the old impeller and gasket, installing the new impeller and gasket, reassembling the lower unit, and refilling the gear oil.

Advantages and Disadvantages of Changing Your Own Impeller

| Advantages | Disadvantages |

|---|---|

| Cost savings compared to professional service | Potential for incorrect installation if not familiar with the process |

| Convenience of doing it yourself on your own schedule | Risk of damaging components if not careful |

Five best practices for impeller replacement include using genuine Suzuki parts, lubricating the impeller with glycerin or soapy water before installation, inspecting the impeller housing for damage or debris, properly aligning the impeller key, and double-checking all connections and bolts after reassembly.

Frequently asked questions include: How often should I replace the impeller? What are the signs of a failing impeller? What tools do I need to change the impeller? What type of impeller do I need for my specific Suzuki outboard model? Can I use automotive grease on the impeller? How do I know if the impeller is installed correctly? How do I drain the lower unit oil? How do I refill the lower unit oil?

Tips and tricks for impeller replacement include taking photos during disassembly to aid in reassembly, using a small pick to remove any remaining pieces of the old impeller, and carefully inspecting the water pump housing for debris.

In conclusion, maintaining a functional impeller is crucial for the health and longevity of your Suzuki outboard. Regularly replacing your impeller, a relatively simple and inexpensive procedure, prevents overheating, ensures optimal engine performance, and saves you from potentially costly repairs in the long run. By understanding the process, gathering the necessary tools, and following the recommended steps, you can keep your Suzuki outboard running smoothly and enjoy countless hours on the water. Don't wait for signs of trouble; be proactive in your maintenance and ensure your outboard's cooling system is always in top condition. Take the time to invest in your outboard's well-being—it will pay dividends in performance and peace of mind on your next boating adventure. Regular maintenance is not just a chore, it's an investment in the future enjoyment of your time on the water.

Ncaa mens tournament bracket predictions mayhem

Unlocking the secrets of 5 pin bowling ball weights

Spinning giants exploring iowas wind turbine landscape