Hydrochloric Acid Safety A Critical Guide

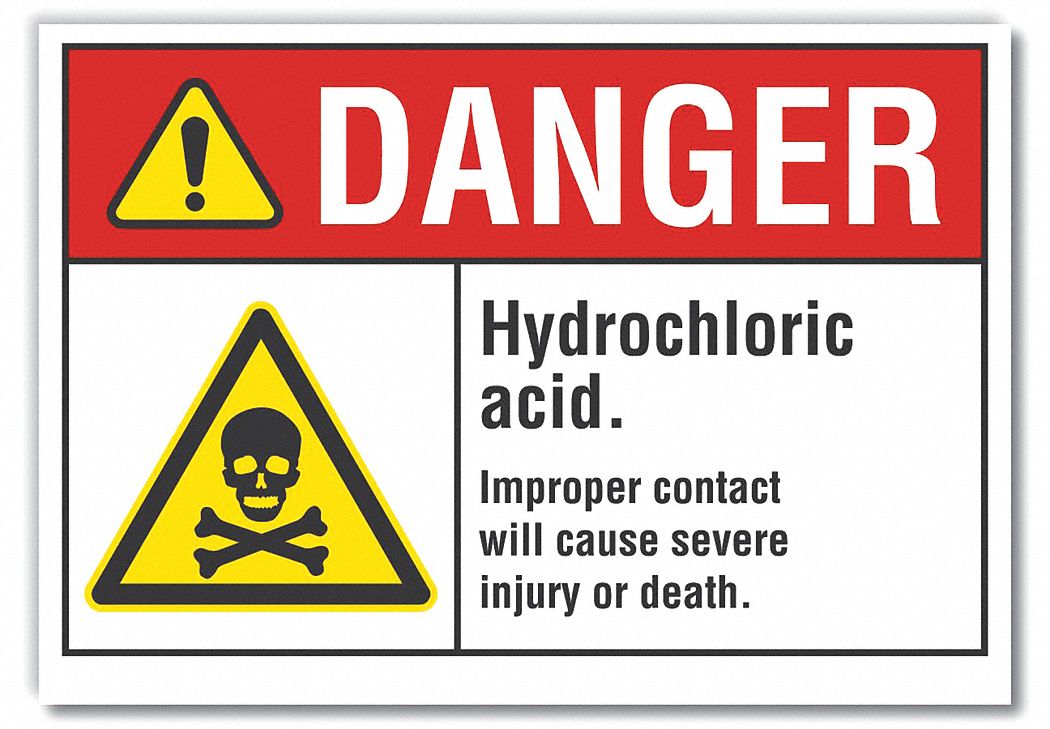

Hydrochloric acid: it's a powerful chemical compound used across a dizzying array of industries, from metal cleaning to food processing. But its strength comes with inherent risks. Ignoring hydrochloric acid safety protocols can lead to serious consequences, impacting both personal well-being and the environment. This guide serves as your essential primer on navigating the complexities of hydrochloric acid safety information.

Understanding the properties of hydrochloric acid is the first step towards safe handling. This highly corrosive acid, in concentrated forms, releases toxic fumes that can severely irritate the respiratory system and eyes. Skin contact can result in chemical burns, and ingestion can cause internal damage. Therefore, proper procedures and precautions are non-negotiable.

Historically, hydrochloric acid, also known as muriatic acid, has played a significant role in various industrial processes. Its usage has evolved, leading to advancements in safety measures and a deeper understanding of its potential hazards. This evolution underscores the importance of staying updated on current hydrochloric acid safety guidelines.

One of the main issues related to hydrochloric acid safety information is ensuring its accessibility and effective dissemination. Clear, concise, and readily available resources are vital for educating individuals and industries on safe handling practices. This includes comprehensive training programs, readily available safety data sheets (SDS), and ongoing updates to reflect evolving best practices.

Effective hydrochloric acid safety relies on a multi-pronged approach. This includes understanding proper storage procedures, using appropriate personal protective equipment (PPE), and knowing how to respond in emergency situations. Safe storage involves designated, well-ventilated areas away from incompatible materials. PPE, including gloves, goggles, and respirators, forms the first line of defense against accidental exposure. Lastly, a well-defined emergency response plan is crucial for mitigating the impact of spills or leaks.

Three key benefits emerge from prioritizing hydrochloric acid safety information. First, it minimizes the risk of accidents and injuries, protecting individuals from harm. Second, it contributes to a safer work environment, boosting productivity and morale. Third, adherence to safety protocols ensures environmental compliance, preventing contamination and protecting ecosystems.

Creating a safe working environment starts with a comprehensive action plan. This involves conducting regular risk assessments, implementing robust safety protocols, and providing ongoing training to personnel. Successful implementation requires active participation from all stakeholders, fostering a culture of safety.

A simple checklist can serve as a powerful tool for reinforcing hydrochloric acid safety measures. This could include verifying proper PPE usage, checking for adequate ventilation, and confirming the availability of spill kits. Regular reviews of this checklist can help maintain vigilance and identify potential gaps in safety protocols.

Advantages and Disadvantages of Robust HCl Safety Information

| Advantages | Disadvantages |

|---|---|

| Reduced accidents and injuries | Initial cost of training and equipment |

| Improved workplace safety culture | Time investment for training and implementation |

| Environmental protection | Potential for complacency if not regularly reinforced |

Five best practices for hydrochloric acid safety include: always add acid to water (never the reverse), work in a well-ventilated area, wear appropriate PPE, inspect containers regularly for leaks, and have a spill kit readily available and know how to use it.

Five real-world examples underscore the importance of hydrochloric acid safety: a worker suffering chemical burns from a spill, a facility being fined for improper storage, a near miss averted by proper PPE usage, an environmental cleanup necessitated by a leak, and a successful emergency response drill preventing a major incident.

Challenges like inadequate training and cost constraints can hinder implementing safety measures. Solutions include leveraging online training resources, seeking grants for safety equipment, and fostering partnerships with safety organizations.

FAQ:

What is the proper way to dilute hydrochloric acid? Always add acid to water slowly, never the reverse, to avoid violent reactions.

What PPE is essential when working with HCl? Gloves, goggles, and respirators are essential.

What should I do if I spill hydrochloric acid? Contain the spill, neutralize it with an appropriate agent, and dispose of it according to regulations. Notify the appropriate authorities if necessary.

Where should HCl be stored? In designated, well-ventilated areas, away from incompatible materials.

What are the signs of HCl exposure? Irritation of the eyes, skin, and respiratory tract, coughing, and difficulty breathing.

What first aid should be administered for HCl exposure? Immediately flush affected areas with water for at least 15 minutes and seek medical attention.

How can I learn more about hydrochloric acid safety? Consult safety data sheets (SDS) and contact your local environmental agency for resources.

Where can I find updated safety regulations? Check with OSHA (Occupational Safety and Health Administration) for the latest guidelines.

Tips for enhancing hydrochloric acid safety include regular safety audits, refresher training sessions, and promoting open communication regarding safety concerns.

In conclusion, prioritizing hydrochloric acid safety information is paramount for protecting individuals, ensuring a safe work environment, and preserving the environment. By understanding the hazards, implementing robust safety protocols, and fostering a culture of safety, we can effectively mitigate the risks associated with this powerful chemical. Regularly reviewing safety procedures, providing ongoing training, and staying updated on the latest best practices are vital steps towards responsible hydrochloric acid handling. Investing in safety is not just a legal obligation; it's a commitment to the well-being of our workforce and the sustainability of our environment. Commit to safety today, and reap the long-term benefits of a safer, more productive tomorrow. Implementing these precautions can significantly minimize the likelihood of accidents, protecting both individuals and the environment. Regularly reviewing safety procedures and providing ongoing training are essential for maintaining a safe and responsible work environment.

Communicating with spirits at home exploring the ghost whisperer phenomenon

Mactan cebu beach resort day use guide

Grand cherokee tow package unleash your adventurous side