Decoding Pneumatic Symbols A Comprehensive Guide

Ever wondered how those intricate diagrams in pneumatic systems make sense? The secret lies in understanding pneumatic symbols. These visual representations are the language of pneumatics, providing a concise and standardized way to depict components and their connections.

Pneumatic symbols are essential for designing, building, maintaining, and troubleshooting pneumatic systems. They offer a universal language that transcends language barriers, enabling engineers and technicians worldwide to interpret and work with pneumatic circuits effectively. This visual shorthand avoids lengthy descriptions and ensures clarity in complex systems.

Imagine trying to describe a complex pneumatic system using only words. It would be a confusing and lengthy process. Pneumatic symbols provide a clear, concise, and standardized way to represent these systems, making them much easier to understand and work with.

The representation of pneumatic components through symbols is crucial for effective communication and collaboration within the pneumatics field. It allows for clear and concise design documentation, troubleshooting guides, and training materials, leading to better understanding and efficient system maintenance.

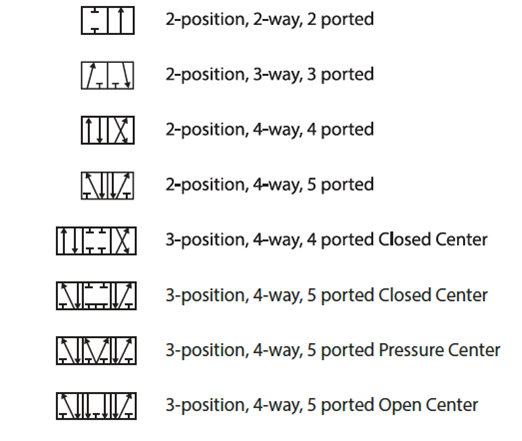

From simple valves to complex actuators, each pneumatic component has its own unique symbol. Learning these symbols is akin to learning the alphabet of pneumatics, paving the way for a deeper understanding of circuit diagrams and system functionality.

The standardization of pneumatic symbols started gaining traction in the mid-20th century with the rise of industrial automation. Organizations like ISO (International Organization for Standardization) played a key role in developing and promoting these standards. This ensured uniformity across different industries and countries. Before standardized symbols, variations in representation often led to misinterpretations and costly errors.

One of the main challenges related to pneumatic symbol interpretation is staying updated with the latest standards and revisions. While ISO standards provide a solid foundation, variations and company-specific symbols can still exist. Therefore, referencing the correct standard for a particular schematic is crucial.

A single-acting cylinder is represented by a rectangle with one piston rod. A double-acting cylinder, on the other hand, has a rectangle with two piston rods. A directional control valve is shown with a box and arrows indicating the flow paths.

Benefits of using standardized pneumatic symbols include: improved communication, reduced design errors, and easier troubleshooting. For example, a technician troubleshooting a faulty system can quickly identify the problematic component based on its symbol in the circuit diagram.

Another benefit is simplified training. New technicians can learn the system faster using clear visual representations.

Furthermore, these symbols foster international collaboration. Engineers from different countries can easily understand and work with each other's designs.

To implement pneumatic symbols effectively, one should first familiarize themselves with the ISO 1219-1 standard. Then, practice reading and interpreting circuit diagrams. Regularly consult relevant resources to stay updated with any changes or revisions to the standards. Using software tools specifically designed for pneumatic circuit design can also be beneficial.

Advantages and Disadvantages of Standardized Pneumatic Symbols

| Advantages | Disadvantages |

|---|---|

| Clear communication | Requires learning and understanding the symbols |

| Reduced errors | Potential for variations or outdated standards |

| Easier troubleshooting | Can be complex for very large systems |

Frequently Asked Questions:

1. What is the ISO standard for pneumatic symbols? Answer: ISO 1219-1

2. Where can I find a complete list of pneumatic symbols? Answer: ISO 1219-1 and various online resources.

3. Are pneumatic symbols universal? Answer: While ISO standards strive for universality, variations can exist.

4. What is the symbol for a pressure relief valve? Answer: A triangle with a spring symbol.

5. How do I interpret a complex pneumatic circuit diagram? Answer: Start by identifying the individual components based on their symbols, then trace the flow paths.

6. Are there software tools for designing pneumatic circuits? Answer: Yes, several software packages are available for this purpose.

7. What are the common mistakes when using pneumatic symbols? Answer: Using outdated symbols or misinterpreting their meaning.

8. How can I stay updated with the latest pneumatic symbol standards? Answer: Regularly consult ISO and other relevant resources.

A tip for understanding pneumatic circuits is to follow the airflow from the compressor to the actuator, identifying each component along the way.

In conclusion, pneumatic symbols are indispensable for anyone working with pneumatic systems. They provide a common language, facilitating clear communication, efficient design, and effective troubleshooting. By understanding and utilizing these symbols, engineers and technicians can create, maintain, and improve pneumatic systems with greater ease and accuracy. The benefits of using standardized symbols are numerous, from reducing design errors and simplifying troubleshooting to enabling global collaboration. Embracing these symbols is a crucial step towards mastering the art of pneumatics. Continuous learning and staying updated with the latest standards are essential for effectively utilizing this powerful visual language and optimizing pneumatic system design and operation. Explore the resources available, practice reading circuit diagrams, and don't hesitate to seek expert guidance when needed. The world of pneumatics awaits your exploration.

Decoding north carolina payroll a comprehensive guide

Birthday blessings kjv bible verses for celebrations

Upgrade your home with the best sherwin williams sage green paints